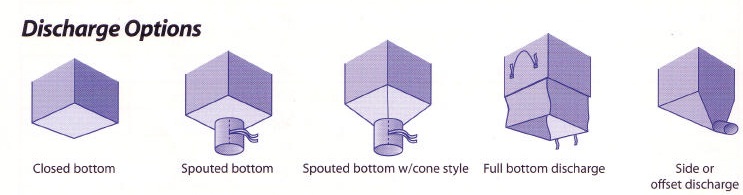

FIBC/Jumbo Bag has gained a reputation for being versatile bulk packaging option in packaging industries. It is an effective bulk packaging for transportation and storing dry flow able products, chemicals etc. FIBC has one customizable closure option at bottom which is useful for unloading materials. There are most common closure option use for your packaging applications.

1. Discharge SproutIn Jumbo Bag discharge sprout is on the bottom of bag which is closed until you open to unload your filled material. This closure option is controlled directly and it does not destroy bag while unloading material. This discharge sprout comes in various sizes and available in customizable option as per your application.

2. Discharge Sprout with Safety ValveSome customize jumbo bags has safety valve for discharge sprout at bottom ideal for choking neck of bag and controlling the flow of material while unloading. This option is mostly used when we have to control the flow of material immediately like hazardous materials.

3. Discharge Sprout with CoverSome FIBC with its discharge sprout has piece of fabric sewn between fabric . Here sprout and petal closure is use to protect the discharge sprout. It prevents contamination by outside threats and minimize bulging. Piece of fabric is sewn on discharge sprout for protection of materials.

4. Discharge Sprout with FlapIn some big bags discharge sprout with flap is known as sanitary flap which protect the entire bottom surface of bag. Bottom surface of bag remains always clean.

5. B-Lock ClosureHere some big bags has b-lock closure option use for safe closing of bulk bags skirt. It is useful to hold rope or coed in place of sprout at bottom of bag. It is available in customizable option.

6. Conical Shape OptionConical closure option is mainly use in conical shape big bags. It has cone shape at bottom of bag. This type of option is suitable for tacky materials which is not freely flow able like clay, slurries.

Mail your Requirement on - enquiry@brainchamber.net